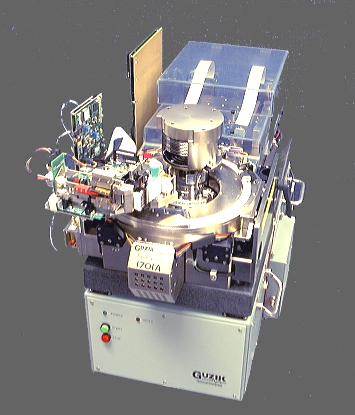

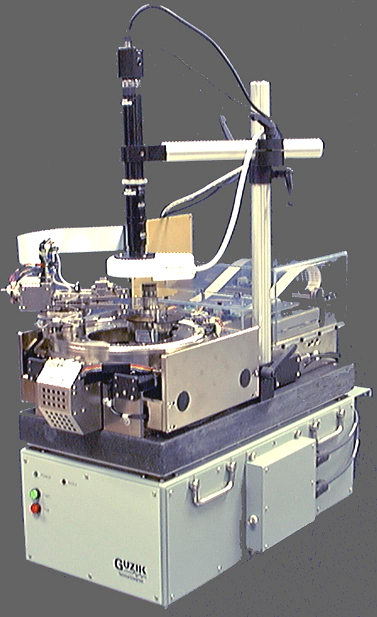

1701A – Obsolete

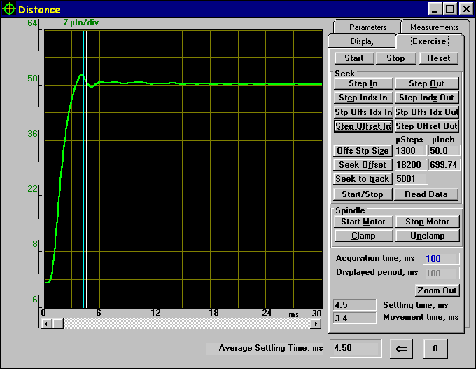

- Improved dynamic characteristics result in shorter settling times.

- Micropositioning system with positioning repeatability1 of 1 µInch.

- Software controlled skew angle conversion without track repositioning.

- Easy conversion between head (HGA) and head stack (HSA) testing.

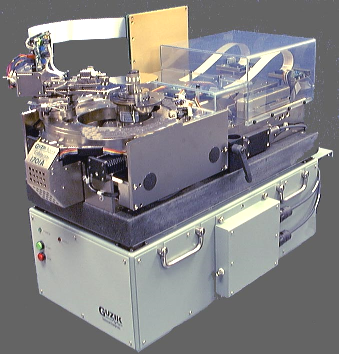

Guzik S-1701A Micro Positioning Spinstand is dynamically improved2 over its predecessors 1701MP and 1701CF. It is equipped with a patented3 closed loop positioning system consisting of a piezo substage and precision optical scales with 0.04 µInch resolution. This results in track positioning repeatability1 of 1 microinch and track profile measurements with effectively zero hysteresis. This capability is a requirement in MR-Head testing and high TPI track profile and track interference analysis.

S-1701A provides software controlled skew angle adjustment through a patented4 software controlled mechanical configuration. Since the head gap is located in the center of a rotational system, skew angle control is accomplished by rotating the head around the head gap. In this manner the skew angle can be changed up to 45 while remaining on the same track.

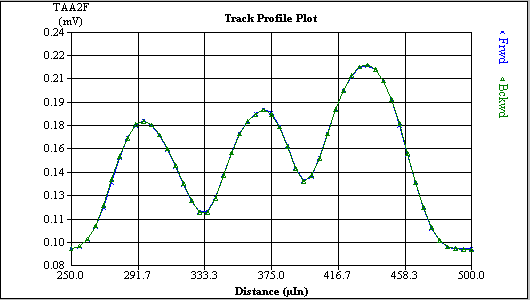

The unique capability of changing skew angles while remaining on track allows the user to perform a variety of measurements, including track profile analysis on a previously written track at varying skew angles. This unique measurement can produce a comb-shaped single-track profile plot.

Through a very simple mechanical conversion, S-1701A can be used for either head (HGA) or head stack (HSA) testing.

- See 1701A Specifications.

- US Patent pending for improved dynamic characteristics.

- US Patent for Closed Loop Positioning System: 5,382,887

- US Patent for mechanical configuration: 5,254,946

Features:

- Settling time improved by 50% compared to 1701MP and 312MP.

- Simultaneous and synchronous rotary and linear stage movements provide correct skew angles at all positions on the disk.

- Universal Micro Positioning Spinstand equipped for HGA, HSA, and Disk testing.

- Positioning repeatability of 1 µInch with optical scale resolution of 0.04 µInch.

- Software controlled skew angles of 45.

- Optional clockwise (mirror) head loader allows testing bottom heads on the top.

- Interchangeable Head Stack (HSA) fixture can be designed to custom specifications.

- Interchangeable “Z-height” adapters, HGA mounting fixtures, and spindle chucks (disk sizes from 1.3″ to 3.5″).

- Air bearing spindles available with programmable speeds 100 – 20,000 RPM.

- Optional optical alignment system available for head gap alignment within .001 Inch to the center of the rotary system.

- Table top unit.

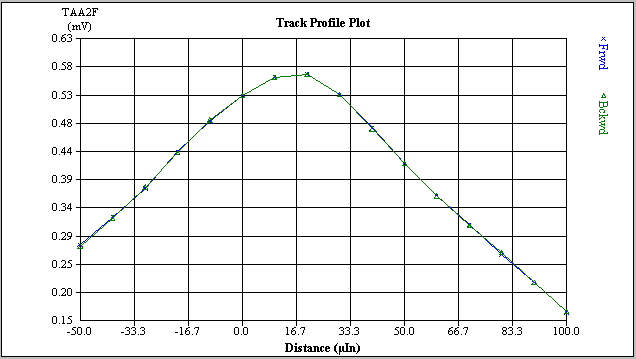

- 20 MHz signal was written on the track.

- The amplitude of the read signal was measured at 10 In increments across the track in both forward and backward directions.

- The resulting Track Profile Plot displays forward, backward, and average results of this measurement. This demonstrates 1 Inch positioning accuracy and zero hysteresis of the Guzik S-1701A spinstand.

- After a band erase, 20 MHz signal was written on the track at -15 skew angle using a Guzik S-1701A spinstand.

- The skew angle of the head gap was changed to 15

- Track Profile at this skew angle was measured ON THE SAME TRACK at 5 I increments. This measurement was performed in both the forward and backward directions. The resulting comb-shaped single-track profile plot displays the amplitude interference introduced by the angle between the magnetic transitions on the track and the head gap.

Settling time is 4.5 ms for a 50 µInch movement (settling tolerance is 1 µInch).

Positioning Mechanism

- Linear Position Repeatability and Local Positioning Accuracy1: ±0.4 µInch typical, ±1 µInch maximum

- Absolute Positioning Accuracy Over the Entire Linear Travel1,2: ±8 µInch typical

- Linear Scale Resolution: 0.04 µInch

- Hysteresis: Closed loop system, no hysteresis

- Skew Angle Range: 45 degrees, software programmable

- Skew Angle Resolution: 1 minute of arc.

Physical

- Size: 24″ x 12″ x 18″

- Weight: 175 lbs

- Power: 110 VAC 15% 50/60 Hz, 3 A approximately

- Power: 230 VAC 15% 50/60 Hz, 2 A approximately

Environmental

- Operational: 15 C to 40 C, 90% maximum relative humidity, with no condensation

Air Bearing Spindle

- Interchangeable Spindle Chucks: 1.3″, 1.8″, 2.5″, 3.5″ available

- Motor: Brushless DC, programmable, 100 RPM – 20,000 RPM

- RPM Jitter: 0.005% typical

- Acceleration: 0 – 10,000 RPM in approximately 3.25 seconds with 3.5″ disk mounted

________________

1 The repeatability and the accuracy can be affected by temperature variations. Due to its low heat capacity, the disk exhibits the fastest response to these variations. Best performance will be achieved at stable environmental temperature and after a warm-up period of approximately 1 hour.

2 Absolute accuracy over the entire range of travel is determined by the accuracy of the linear encoders. Higher precision encoders can be provided on demand, with absolute accuracy of 4 µInch (maximum) over the entire range.