V2002 Spinstand Automation for Media Testing

V2002 Spinstand Automation for Media Testing

Automated Disk Shroud Movement and Replacement of Vacuum Chuck Cap:

- Most effective for media testing, when changing media frequently is a requirement.

- Reduces the time required to remove and replace the chuck cap and move the shroud back and forth when media is changed.

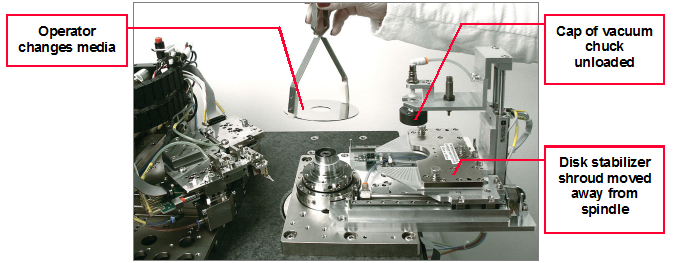

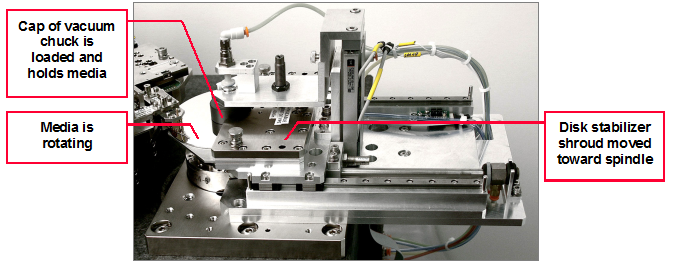

- Simultaneously moves both the shroud and the chuck cap into and out of testing position. The operator just changes the media (see Figures 1 and 2).

- Automated disk shroud movement eliminates the need to manually release, move, and lock the disk stabilizer shroud during media changes. Shroud position sensors ensure that the shroud is in place around the disk before testing begins.

- Interchangeable shroud enables switching between different thickness and media sizes without shimming each shroud.

- The automated disk shroud can be used with a fixed chuck.

The spinstand V2002 with the media-testing automation loads and unloads the cap of the vacuum chuck1 and moves the disk stabilizer shroud on and off media without operator’s intervention. As a result, less time is required for a media replacement, so the same number of disks can be tested faster.

The automation for vacuum chuck1 is optional. The automation for the disk stabilizer shroud is integrated into new V2002 spinstands and can be used for applications other than media testing to avoid moving the shroud manually. Both automation types are available for V2002 revision 9 and later.

Figure 1: The shroud and the chuck cap are in the testing position.