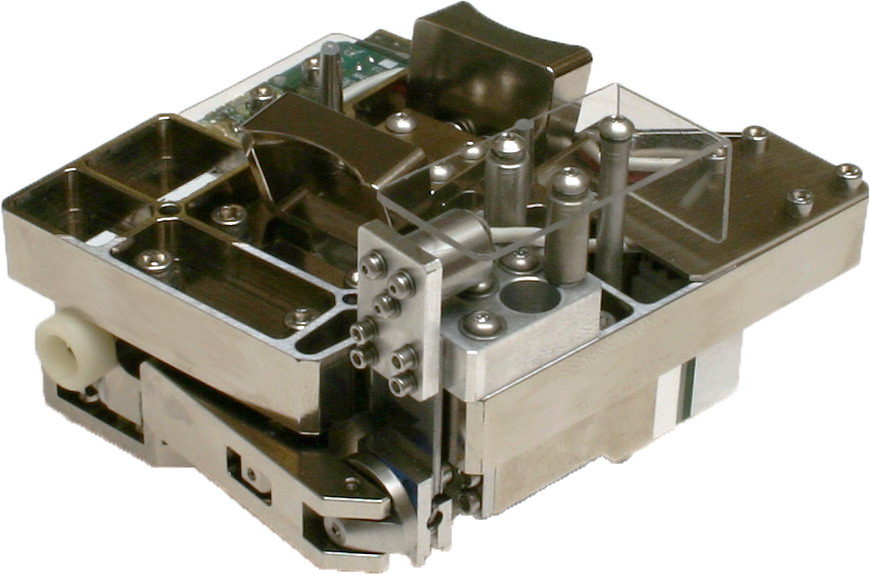

Piezo-Actuator Cartridge with AE Sensor

- Typical Non-Repeatable Run-Out (NRRO) 0.35–0.60 nm (0.014–0.024 mInch), 1 s

- Servo Bandwidth 2–3 kHz

- Improved Test Time

- Estimated Spinstand Capability

420–720 kTPI - Integrated AE Sensor

The new generation of Guzik cartridges1 is equipped with Piezo actuator to achieve higher servo closed loop bandwidth. The typical bandwidth is in the range of 2–3 kHz. This allows for non-repeatable run-out reduction down to 0.35–0.60 nm (0.014–0.024 mInch)2, 1s. The higher servo bandwidth also improves seek time, which leads to test time improvement for several tests.

________________

1 Patent Pending

2 Typical value. Measurement results may vary for different head types.

TPI Capability

The TPI capability of a tester is normally calculated such that the error of the measurement does not exceed some percentage of the magnetic head Track Size. One of the recommended criteria is that 1s of NRRO does not exceed 1% of the Track Size. Based on this criteria the 0.35–0.60 nm (0.014–0.024 mInch) would be 1% of the 1.4–2.4 mInch wide head, which means that the DTR3000 / V2002 tester capability with Piezo-Actuator Cartridge is 420–720 kTPI.

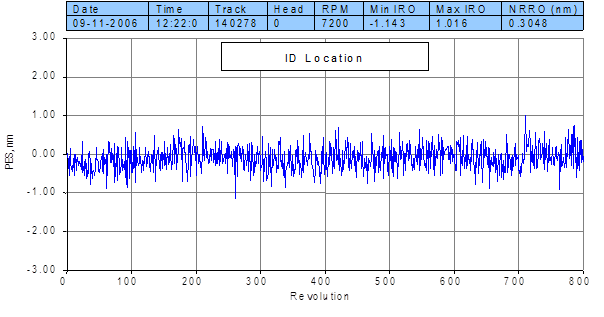

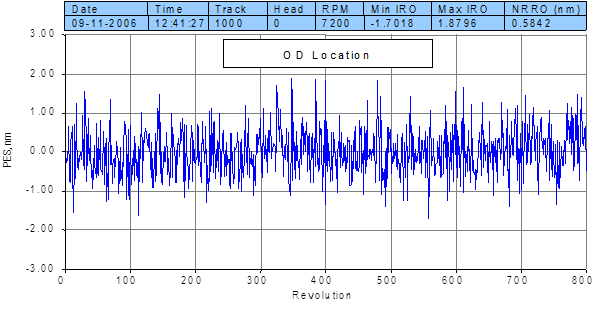

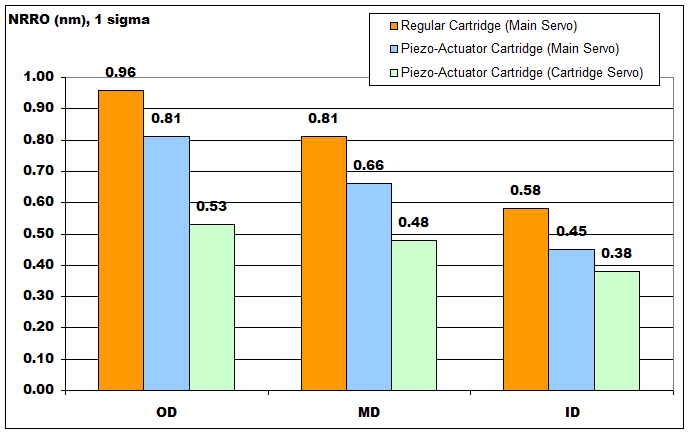

Non-Repeatable Run-Out Improvement

The figures below illustrate the 0.35–0.60 nm (0.014–0.024 mInch) NRRO with Piezo-Actuator Cartridge. The data was measured using 7200 RPM product.

Figure 1: Position Error Signal at ID

Figure 2: Position Error Signal at OD

The Figure 3 below compares V2002 spinstand performance in three configurations:

- With the Regular Cartridge. Standard bandwidth servo loop is enabled, using the main piezo actuator of a spinstand.

- With the new Piezo-Actuator Cartridge. Standard bandwidth servo loop is enabled, using the main piezo actuator of a spinstand. The piezo actuator on the cartridge is not used.

- With the new Piezo-Actuator Cartridge. High-bandwidth servo loop is enabled, using the piezo actuator on the cartridge.

The Piezo-Actuator Cartridge and the Regular Cartridge are interchangeable on the same spinstand without need to realign the spinstand.

Figure 3: Cartridge Comparison

When you use the new Piezo-Actuator Cartridge and enable the high-bandwidth servo loop, you will typically get 35–45% improvement in NRRO, shown in green.

The figure above also shows that the new Piezo-Actuator Cartridge is a more stable platform comparing to Regular Cartridge. It delivers 15–20% better NRRO results, shown in blue, even if you do not enable the high-bandwidth servo loop using the piezo on the cartridge.

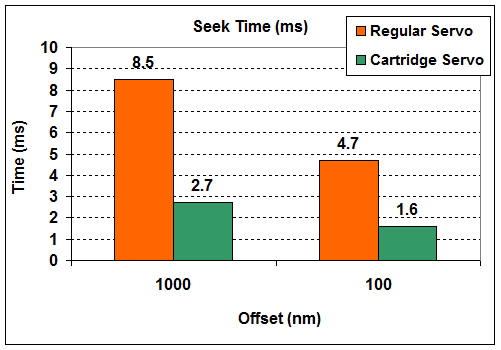

Test Time Improvement

When the high-bandwidth servo loop using the Piezo-Actuator Cartridge is enabled, typical production tests run up to 10–15% faster compared to the regular servo mode3.

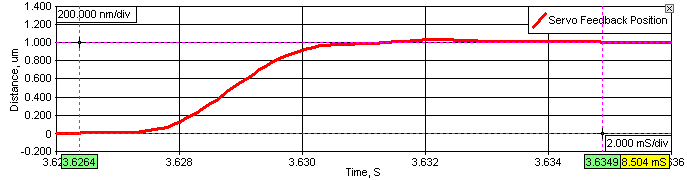

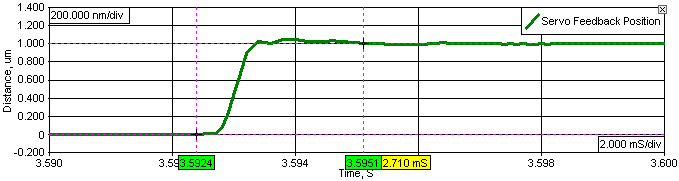

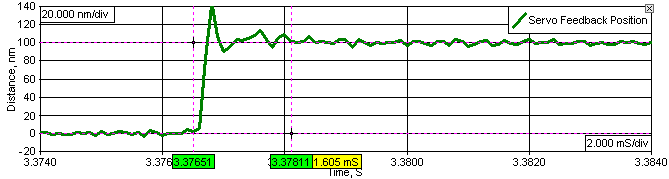

The test time improves because the higher bandwidth servo loop provides for shorter seek time. Please refer to the figures below to compare the difference between seek time using the regular servo4 and the piezo actuator cartridge servo.

________________

3 It is recommended that you purchase an optional Immediate Start Mode license to achieve the best test time.

4 Actuation is performed using the main piezo of Guzik V2002 spinstand. Spinstand revision 11 was used for the measurement.

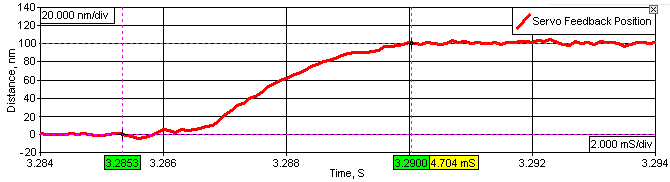

Figure 4: Regular Servo – 8.5ms Seek Time for 1000nm Offset

Figure 5: Cartridge Servo – 2.7ms Seek Time for 1000nm Offset

Figure 6: Regular Servo – 4.7ms Seek Time for 100nm Offset

Figure 7: Cartridge Servo – 1.6ms Seek Time for 100nm Offset

Figure 8: Seek Time Comparison

Integrated AE Sensor

AE sensor is integrated with the Piezo-Actuator Cartridge and has the following features and parameters:

- AE sensor is mechanically coupled with the head-mounting block.

- AE sensor is integrated with the first stage of the amplifier in one unit to reduce electrical noise.

- Electrical connection is done through pogo pins with sliding mechanism, which eliminates the need of a permanent cable connection.

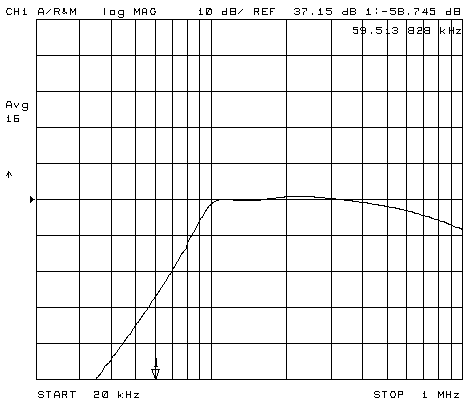

- The acoustic amplifier has the total 60 dB gain and 100 kHz – 600 kHz bandwidth (-3dB), see Figure 9. The 5-pole high pass filter is used to suppress low frequency noise, coming from servo loop, various mechanical components and switching power supply.

- Output – MCX connector, 50 Ohm termination, located on the spinstand back panel.

Figure 9: AE sensor filter frequency response

TFC touchdown test is available in WITE32 Revision 4.20 or later.

The output acoustic signal goes to an external PC oscilloscope PicoScope 3224 for data acquisition and observation. The signal is digitized by the PicoScope and then sent to the

PC via USB interface for further processing.

Initially TFC touchdown test sets the TFC power to a minimum value and then gradually increases it until the touchdown event is detected by measuring the acoustic emission by

the AE sensor. It also calculates the Backoff TFC for the specified flying height and

optionally sets the TFC as a system value.

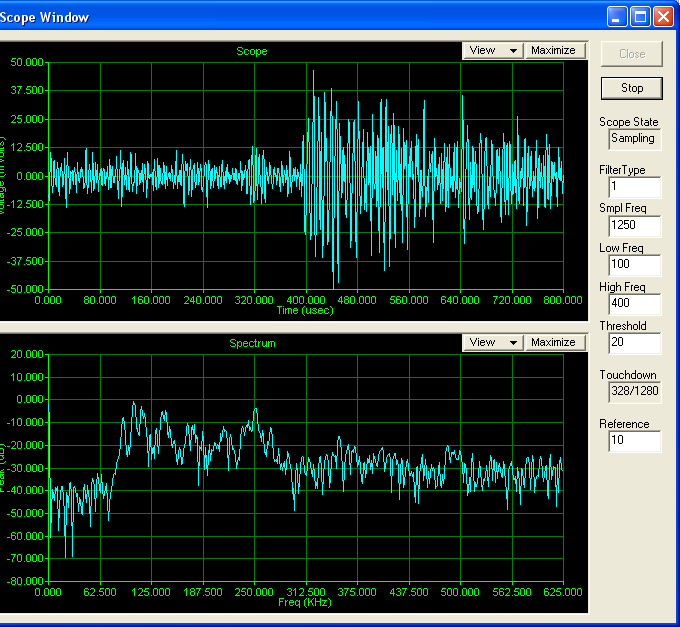

Figure 10 shows AE signal during the initial touchdown. For further details, please see

WITE32 TFC Tests User’s Guide P/N 02-107526-01.

Figure 10: AE signal in time domain and frequency domain during initial touchdown

System Requirements

The following test system components are required:

Guzik DTR3000 spinstand, or V2002 spinstand revision 6 or higher with the following components:

- Head Loading Mechanism upgraded with piezo-actuator cartridge interface,

- Control Interface Board P/N 321850,

- Combloader Interface Board P/N 324250 or 328390.

Spinstand Control Box SCB DTR3000, or SCB V2002 with the following components:

- Servo Driver 5 board P/N 330880 (revision ‘B’ Dual Channel),

- Servo Controller 5 board P/N 330890 (any revision), or Servo Controller 6 board P/N 335900 (any revision)

- Coldfire III Microprocessor board P/N 317950 (revision “T”)

Guzik Read Write Analyzer:

- RWA-3000 DTR series, or

- RWA-2000 series with Servo Revision 4, or

- RWA-2000 series with Servo Revision 3.

TFC Module Bundle for TFC Touchdown Test.

It is recommended that your RWA-2000 series has RWA Control 2 Board P/N 3258005.

It is recommended that you purchase an optional Immediate Start Mode license to achieve the best test time with Piezo Actuator Cartridge.

WITE32 Software Revision 4.20 or later.

________________

5 If your RWA has an older RWA Control Board P/N 306180, you will not be able to use the Enhanced Performance Mode 2 (Partial Revolution) with the high number of sectors required for Piezo Actuator Cartridge. For compatibility verification and upgrade quotation please send RWA and Spinstand EEPROM Dump information to sales@www.guzik.com.