V2002 Spinstand Automation for Head Testing

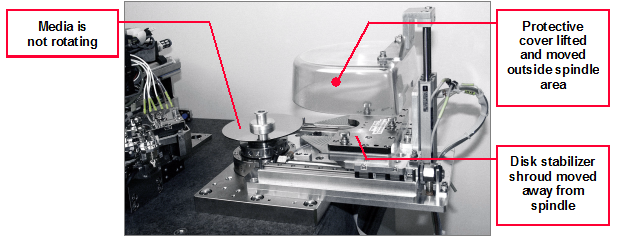

Automated Protective Cover and Disk Shroud:

- Improves the repeatability and the accuracy of HGA testing results.

- Protects media and operator while changing HGA cartridges without stopping spindle.

- Covers media to protect it while spinstand is not in use.

- Automated disk shroud movement eliminates the need to manually release, move, and lock the disk stabilizer shroud during media changes. Shroud position sensors ensure that the shroud is in place around the disk before testing begins.

- Interchangeable shroud enables switching between different thickness and media sizes without shimming each shroud.

- The automated disk shroud can be used with the vacuum and the fixed chucks.

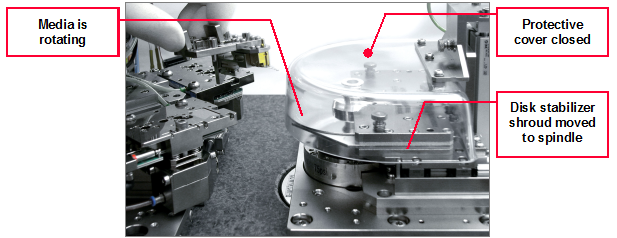

The automated protective cover and the disk-shroud automation add more to the V2002 head-testing capability: with the protective cover closed, the operator can safely change the cartridges without stopping the spindle.

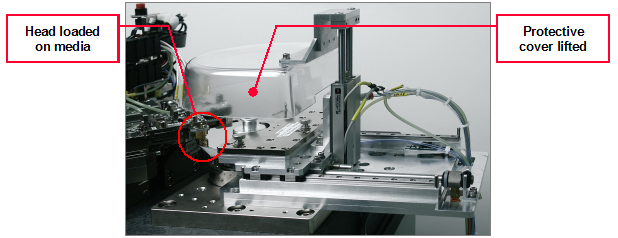

Keeping media rotating during the head changes eliminates the RRO drifts associated with starting and stopping the spindle and increases the repeatability of the test results. The cover automatically opens before loading the head onto the media, closes after the head unloading, and moves

outside the spindle area, together with the disk stabilizer shroud, for media replacement after

the test completion.

The automation is available for V2002 revision 9 and later. The protective cover is an option. The automation for the disk stabilizer shroud is integrated into new V2002 spinstands and can be used without the protective cover to avoid moving the shroud manually.

Figure 1: Now the protective cover is closed, and the operator can replace the cartridge

safely, without stopping media rotation.

Figure 2: The protective cover is lifted to enable head testing.